About Alcoa

Alcoa is the world’s leading producer and manager of primary aluminium, fabricated aluminium and alumina facilities, and is active in all major aspects of the industry.

Alcoa serves the aerospace, automotive, packaging, building and construction, commercial transportation and industrial markets, bringing design, engineering, production and other capabilities of Alcoa’s businesses to customers and employs approximately 61,000 people in 30 countries across the world.

Quasar – Partnering with Honeywell

Alcoa turned to Fortune 100 Technologies leader Honeywell to provide standardized process control infrastructure and control solutions across multiple refineries in six countries.

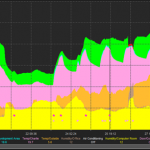

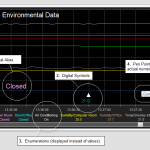

The partnership resulted in a strategic program known as Quality Automation Solutions in Alumina Refining (QUASAR). By improving Alcoa’s plant efficiency, reducing raw materials consumption and lowering environmental emissions, QUASAR provides Alcoa with a sustainable, competitive advantage.

One of the key aims of QUASAR program was to deliver improved process performance by leveraging automation technology and combining best practices from each refinery.

In 2012 when a new trend control was required due to migration of the process control hardware to Windows-7, Honeywell approached Jemmac to help satisfy Alcoa’s requirements.

SapphireTrend

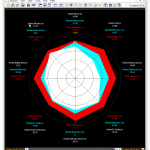

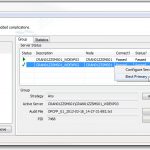

Jemmac’s flagship product SapphireTrend includes an advanced Active-X trend control (stOCX) that met the technical requirements for Quasar and was well proven having been used globally by one of the worlds leading Oil & Petrochemical multinationals since it’s launch in 2003.

A deal was quickly struck for Jemmac to supply stOCX to Honeywell along with making a number of modifications required to allow stOCX to seamlessly replace the existing trend controls that were unable to be migrated to Windows-7.

Successful Outcome

After a period of close collaboration between Jemmac in the UK, and Honeywell in Perth, Australia an OEM version of SapphireTrend’s Active-X control stOCX was delivered to a delighted customer.

Roy Lumley (Honeywell Operator Effectiveness Lead) said:”Honeywell was faced with the challenge of making their legacy GUSPro Trend solutions run in a Windows-7 environment. After exploring the option of investing significant development effort to migrate the legacy trend objects, Honeywell made the decision to use Sapphire Trend instead. Sapphire Trend was already qualified on Windows-7 so integrating it into the existing GUS solution for Alcoa/QUASAR was a good decision.”

“The extensive configuration options in stOCX allowed us to quickly produce a trend which mimicked GUSPro Trend. Where differences did exist we were able to work with Jemmac to agree the modifications required to address them. The resulting changes were implemented quickly and efficiently allowing us to meet our project timescales.”

“Although the development between Honeywell/Jemmac was coordinated remotely, the Jemmac developers were able to obtain a clear understanding of our design requirements without the need a URS/DFS for them to interpret or even lengthy design meetings. Moreover Jemmac was able to coordinate the remote testing and diagnostics of their interim builds on our local development system in spite of the distances and time zone differences. They have been a pleasure to work with.”James Weedon, SapphireTrend Product Manager and Director of Jemmac Software said:”It is always interesting hearing other peoples take on how trending and advanced process visualisation should work. Whereas existings customers tend to use the Sapphire Collector or OPC HDA (Historical Data Access) to provide the data for their trends Honeywell were wanting to make a single history fetch (OPC HDA) to intially seed the trend with incremental updates then being made via OPC DA (Data Access).”

“This required some architectural revisions to our control, but was something we were happy to embrace as it increased the flexibility of our product. During this process Honeywell were very helpful communicating requirements concisely and helping with the testing and benchmarking required to make sure the changes would meet their customers needs, whilst being both robust and performant.”

For more information, contact:

James Weedon

Jemmac Software Limited.

Tel : 01234 757252

Email : james.weedon@jemmac.com

Additionally, see the Product page to find out more.